Position title

Process Optimizer in Plastics Technology (m/f/d)

Description

We are currently looking for a process optimizer (m/f/d) to join our team.

Responsibilities

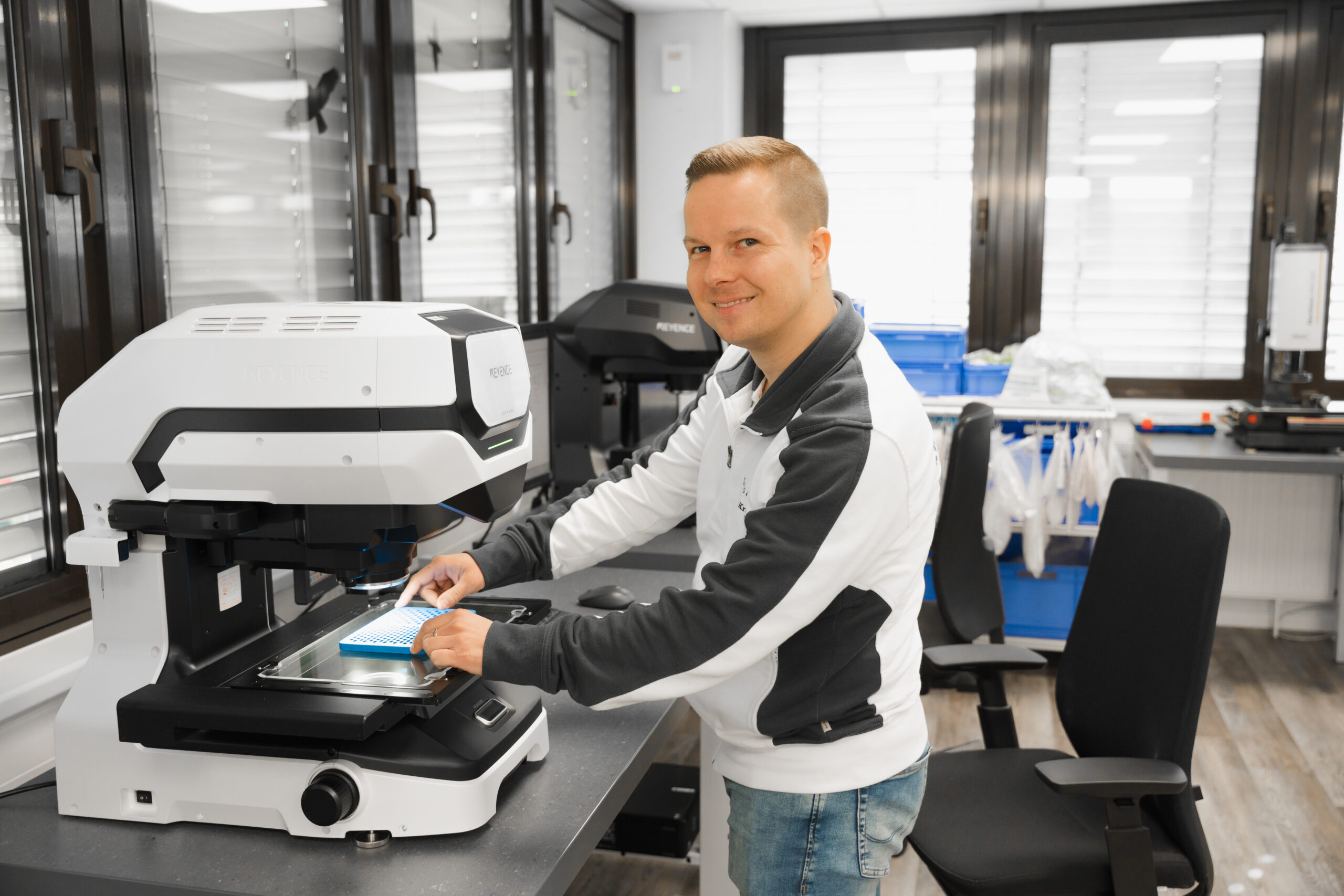

- Analysis of existing processes and procedures, as well as their optimization in plastics manufacturing

- Optimization of injection molding processes in terms of quality, cycle time, and process reliability

- Introduction and optimization of technologies

- Conducting training and instruction

- Sampling of new tools and materials

- Preparing and carrying out conversion and adjustment work on injection molding machines and their peripherals

- Identifying disruptions in the production process and taking measures to eliminate them permanently

- Quality testing and evaluation of finished products

Qualifications

- Successfully completed training as a plastics moulder (m/f/d) or process mechanic for plastics and rubber technology (m/f/d) or tool mechanic (m/f/d) in the field of plastic injection moulding – ideally further training as a master craftsman (m/f/d) or technician (m/f/d)

- Experience in sampling new tools and optimizing manufacturing processes in plastic injection molding

- Excellent knowledge of machines and tools

- Strong technical understanding and quality awareness

- Good communication skills, initiative, and flexibility

- Basic knowledge of IT systems

- Process- and team-oriented thinking

- Goal-oriented and structured way of working

- Commitment

- Good communication and teamwork skills

Contacts

Tel.: +49 6172 9570-0

E-mail: bewerbung@spang-brands.de

Wir bieten

- Permanent employment contract

- Performance-based remuneration

- 30 days of vacation

- Vacation and Christmas bonuses

- Company parking spaces

- Bicycle leasing (Jobrad) / corporate benefits

- Contribution to company pension plan

- Excellent training and continuing education opportunities

- Company events

Hiring organization

Employment Type

Full-time

Job Location

Max-Planck-Straße 25, Friedrichsdorf, Hesse, 61381, Germany

PDF Export