Product development

Product development

Product development

From concept to production readiness

Whether it’s an innovative product idea or a specific market requirement, we support you in every phase of product development with a clear goal:

Transforming your vision into a finished, production-ready product safely, quickly, and precisely.

Our services cover the entire process chain—from design development and the manufacture of prototypes and tools to the series production of high-precision plastic parts for medical technology.

We take a holistic and interdisciplinary approach:

- Design for manufacturing

- Material selection

- Functionality

- regulatory requirements

- etc.

All relevant factors are incorporated into the process from the outset.

Satisfaction

- Custom product development

- Application-specific material selection

- Customized 3D models

- Quality toolmaking

Additional services:

Advantages

Your Advantages with Us!

Innovative

Forward-looking

solutions for medical technology

Competent

100 years of expertise for products you can rely on.

Individual

Customized

products that perfectly match your requirements.

Qualitative

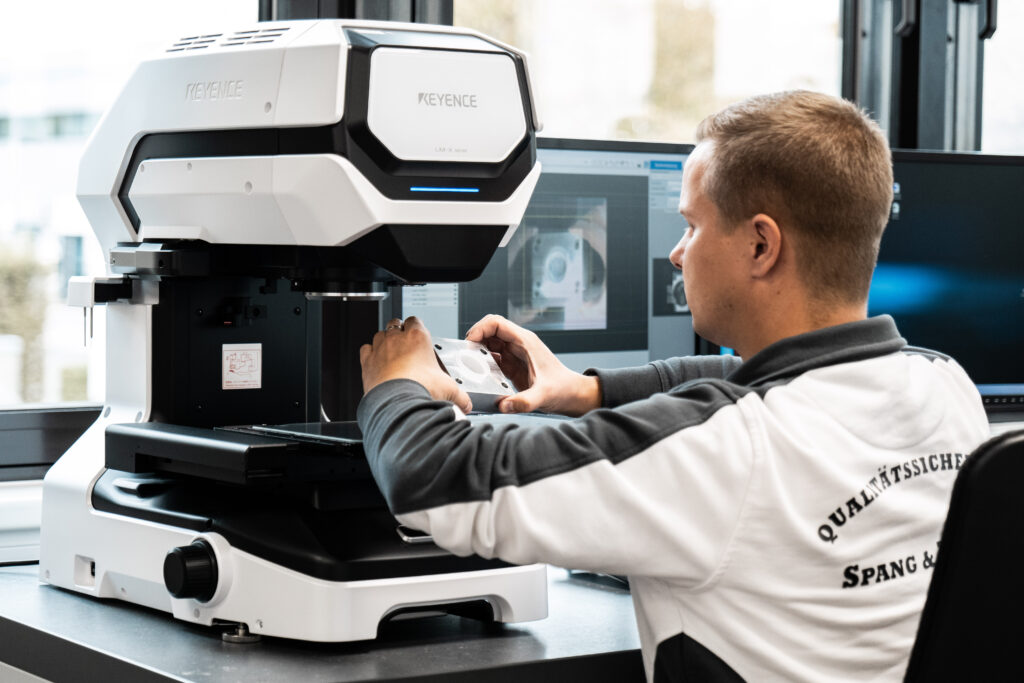

Precise products of the highest quality – certified and reliable.

More information

During the product development process (PDP), we support our customers with clear, systematic analyses and provide reliable assessments of feasibility, quality, and cost-effectiveness. In doing so, we consistently work according to the principles of object-oriented design—from design to quality to design for manufacturing.

In addition to product development, we also support you in selecting and designing the appropriate manufacturing and processing technologies. The required assembly and automation concept is determined entirely according to your individual requirements and quantities.

Process

Our Approach

1. Consultation

We start with an individual consultation to understand your requirements precisely. From material selection to special technical requirements.

2. Design

We work closely with you to develop customized products, create prototypes, and test functionality and quality—all according to your specifications.

3. Production

With state-of-the-art manufacturing techniques and strict quality control, we guarantee that only products that meet the highest standards are delivered to you.

4. Delivery

After production, we always deliver on time and offer you reliable after-sales service to ensure that your product functions optimally and durably under all conditions.

Common problems

1. Strict regulations & approval hurdles: Medical technology is a highly regulated industry with strict approval requirements. Many service providers do not have the necessary expertise to prepare products for the market quickly and efficiently.

2. Lack of material expertise: Choosing the right material is crucial. Without in-depth knowledge of biocompatible plastics and the specific requirements for medical applications, poor decisions can compromise product safety.

3. Slow market launch: Without precise development processes and rapid prototype production, market launch is delayed—opportunities, sales, and market share are lost, costs rise, and competitors are the first to meet demand.

Our solutions

1. Expertise in regulations: With our many years of experience and in-depth knowledge of regulatory requirements, we ensure that your product receives all necessary certifications quickly and reliably.

2. Material expertise & innovation: We specifically select the best materials that offer maximum safety, performance, and durability. Each material is tested in practical applications and documented in accordance with standards—this is how we ensure functional, scalable, and consistently compliant production.

3. Rapid prototyping: Thanks to our efficient development processes and the use of state-of-the-art manufacturing technologies, we can quickly deliver functional prototypes, which accelerates your market launch and minimizes risks.

FAQ

Frequently asked questions

We accompany you from the initial idea to the finished product. First, we create a concept and a 3D model, which we coordinate with you. This is followed by the production of prototypes and testing. If everything fits, we move on to series production. We keep you closely informed throughout the entire process.

The duration varies depending on the complexity of the project. A simple development process can take a few weeks, while more complex products may require several months. However, we optimize all steps to shorten the time to the finished product.

Prototypes are an essential part of the development process. They enable us to review the design and identify potential problems at an early stage. We test the prototypes together with you to ensure that the product meets your requirements.

Yes, we offer small batch production as well as large volume manufacturing. We ensure efficient production and high quality, regardless of the quantity.

Should problems arise during production or use, we offer maintenance and repair services. We are also available to assist you after production to ensure that your product always functions perfectly.